Beautiful And Strong Polished Concrete Solutions

Luxury Polished Concrete Floors

Modern and Sustainable Flooring: Polished Concrete

Polished concrete is a versatile flooring solution that transforms existing concrete surfaces into durable, attractive, and low-maintenance floors. Originally developed for commercial use, polished concrete has become a popular choice for residential, retail, and commercial applications due to its modern aesthetics and long-lasting performance.

How Polished Concrete Works

The installation process involves grinding the concrete surface with progressively finer diamond abrasives, much like polishing natural stone, such as granite. This technique creates a smooth, high-gloss finish with similar wear characteristics to stone, offering both beauty and functionality.

Polished vs. Stained Concrete

While polished concrete and stained concrete may look similar at first glance, the two are quite different in terms of durability and maintenance:

- Stained Concrete: Depends on a surface sealer to protect the floor. This top layer is prone to wear and failure over time, making it less durable in high-traffic areas.

- Polished Concrete: Uses sealers that penetrate the concrete, eliminating the need for a surface layer that can wear or fail. This makes polished concrete significantly more durable and ideal for both residential and commercial spaces.

Why Choose Polished Concrete?

- Sustainability: Utilizes the existing concrete, reducing material waste.

- Durability: Resists wear without a vulnerable surface sealer.

- Modern Appeal: Offers a sleek, contemporary look that complements any space.

Polished concrete is the perfect combination of beauty, strength, and sustainability, making it a smart choice for modern flooring needs.

Polished Concrete Installation Guide

The term polished concrete often causes confusion. Does it refer to the level of reflectivity of the concrete surface? Surprisingly, it does not. Instead, the term signifies that penetrating sealers are used to enhance the stain resistance of concrete surfaces, not their shine. While the industry standard reflectivity level is a semi-gloss finish (800 grit diamond polish), polished concrete can be customized to achieve a matte or mirror-like finish.

Consistency Across Reflectivity Levels

Regardless of reflectivity, polished concrete surfaces are exceptionally smooth and consistent to the touch. This finely honed texture plays a crucial role in creating a slip-resistant, durable, and low-maintenance flooring option suitable for a variety of spaces.

Choosing Your Reflectivity Level

One of the most important aesthetic choices in concrete flooring installation is selecting the level of reflectivity:

- Matte Finish: Often favored in modern or minimalist design projects.

- High Gloss Finish: Ideal for increasing light and creating a sense of openness in darker or smaller spaces.

Reflectivity is purely an aesthetic decision and does not affect the durability or performance of the floor. Additionally, it has a minimal impact on the cost per square foot.

Why Reflectivity Matters

Choosing the right reflectivity level allows you to align the flooring’s appearance with the overall design of the space while benefiting from polished concrete’s inherent durability, stain resistance, and low maintenance.

Choosing the Level of Aggregate Exposure for Polished Concrete

Aggregate exposure is another critical aesthetic decision when installing polished concrete floors. Achieved by removing the superficial surface layers of a concrete slab prior to polishing, aggregate exposure reveals the underlying materials—liquid cement, rocks, and sand—that make up the concrete. The deeper the grind, the more aggregate is exposed, with larger aggregates revealed at greater depths due to their natural separation during the concrete pouring process.

Types of Aggregate Exposure

1. Cream Polished Concrete

- Description: A polished concrete floor with no surface grinding, leaving the top layer intact. These floors showcase natural variations in texture, often compared to marble.

- Applications: Cream-polished floors are cost-effective and commonly used in residential construction where budget-friendly solutions are prioritized.

- Aesthetic Appeal: Despite being the least labor-intensive, cream finishes can look stunning when properly polished and sealed, adding subtle elegance to any space.

2. Salt and Pepper Polished Concrete

- Description: Light grinding removes the surface layer, exposing fine particles of sand and small rocks, creating a smooth and homogenous finish.

- Applications: Frequently installed in retail stores like Costco, Walmart, and Home Depot, as well as in luxury residential projects.

- Aesthetic Appeal: Offers a clean, consistent appearance that complements modern designs. This is the most popular choice for homeowners seeking both style and durability.

3. Rock-Cut Polished Concrete

- Description: Heavy grinding exposes large aggregates, giving the floor a terrazzo-like appearance that’s ideal for modern and industrial aesthetics.

- Applications: Best suited for new construction or fully gutted renovations, as the process requires extensive material removal and is difficult with existing obstacles like trim or millwork.

- Aesthetic Appeal: This finish delivers a striking, high-end look but requires the most time, effort, and budget to achieve.

Why Aggregate Exposure Matters

Each level of aggregate exposure offers unique visual and functional benefits, allowing you to tailor the flooring to your design preferences and budget. Whether you choose the subtle elegance of a cream-polished floor, the modern uniformity of salt and pepper, or the bold terrazzo-like appeal of rock-cut concrete, polished concrete provides a durable, stylish solution for residential and commercial spaces alike.

Services

Driveway Sealcoating

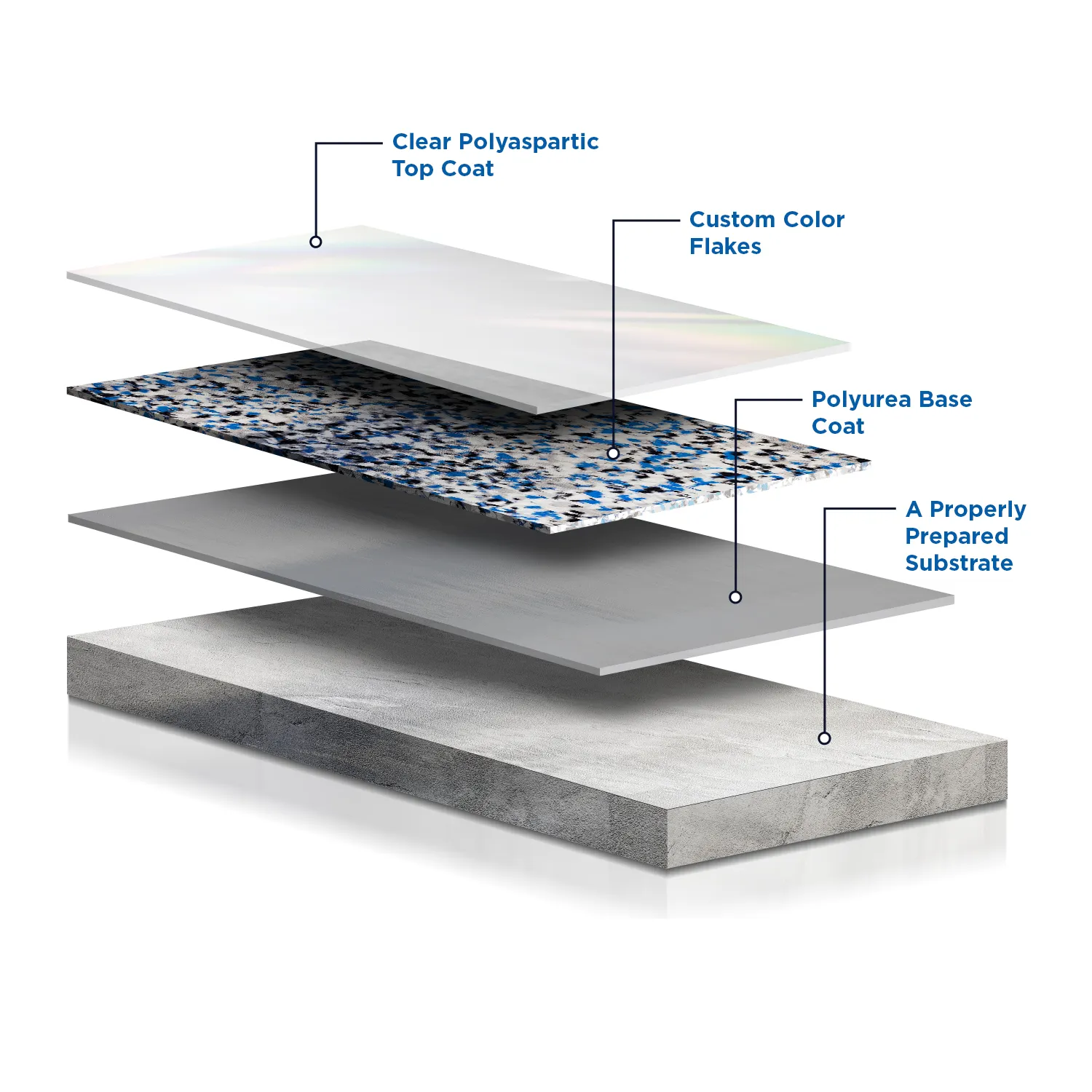

Garage Floor Coating

Asphalt Maintenance

Commercial Flooring

Corporate Office

11262 Kilmer Rd

Edison, NJ 08872

Phone

NJ (732-524-7757

VA (804) 234-3180